LUG Light Factory is a leading electronics manufacturer offering comprehensive EMS (Electronic Manufacturing Services) services. We specialise in providing manufacturing solutions for clients in a wide range of industries, ensuring high quality, flexibility, and timely delivery of projects. Our main EMS services include:

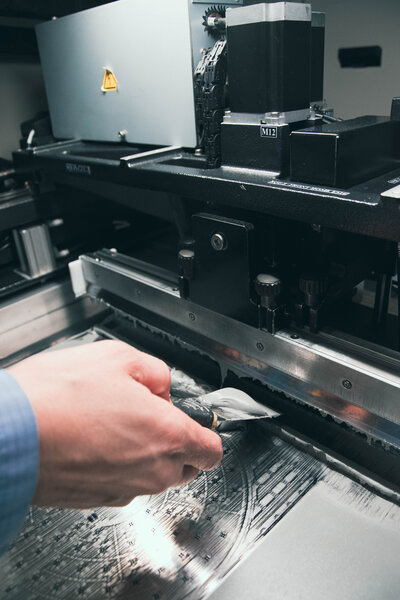

Laser Marking

The Asys INSIGNUM laser marking machine is a revolutionary solution designed for the permanent marking of a variety of materials such as PCBs, ceramics, plastics, and DBC substrates with a precise laser beam. It introduces a new quality in identification by giving each module a unique serial number, which can then be scanned by every machine in the production line.

The marking machine enables precise marking anywhere on the module, thanks to advanced head movement systems. Equipped with intuitive SIMPLEX software, it offers a unique human-machine interface for easy programme creation, laser marking process monitoring, and design and customisation of 1D and 2D codes.

An integrated PCB turning station for double-sided marking of large-format PCBs makes it even more flexible.

Services

We offer a wide range of EMS services, including surface-mount technology (SMT), conventional assembly (THT), conformal coating, testing, quality inspection, and a comprehensive logistics service. Our flexibility allows us to tailor our services to individual customer needs, providing comprehensive support at every stage of production.

Automated Component Placement (Pick & Place)

The machine provides stable operation based on an autonomous function that reduces workload and improves productivity through concentrated control. Improved navigation and automated elements, such as feeder configuration navigation and component delivery, eliminate variations in the work and streamline the assembly process.

Panasonic machines are equipped with the PanaCim system. The system can handle all MES functions at line and floor level, supporting Panasonic and partner equipment. This improves quality control with fewer defects as well as reduced waste and rework. The powerful MES technology with a modular design means new solutions can be added as needed.

This software package goes beyond SMT and now includes capabilities for: material control, traceability, production analysis, production monitoring and dispatch, production planning, material verification, maintenance, product change and control, and data linking.

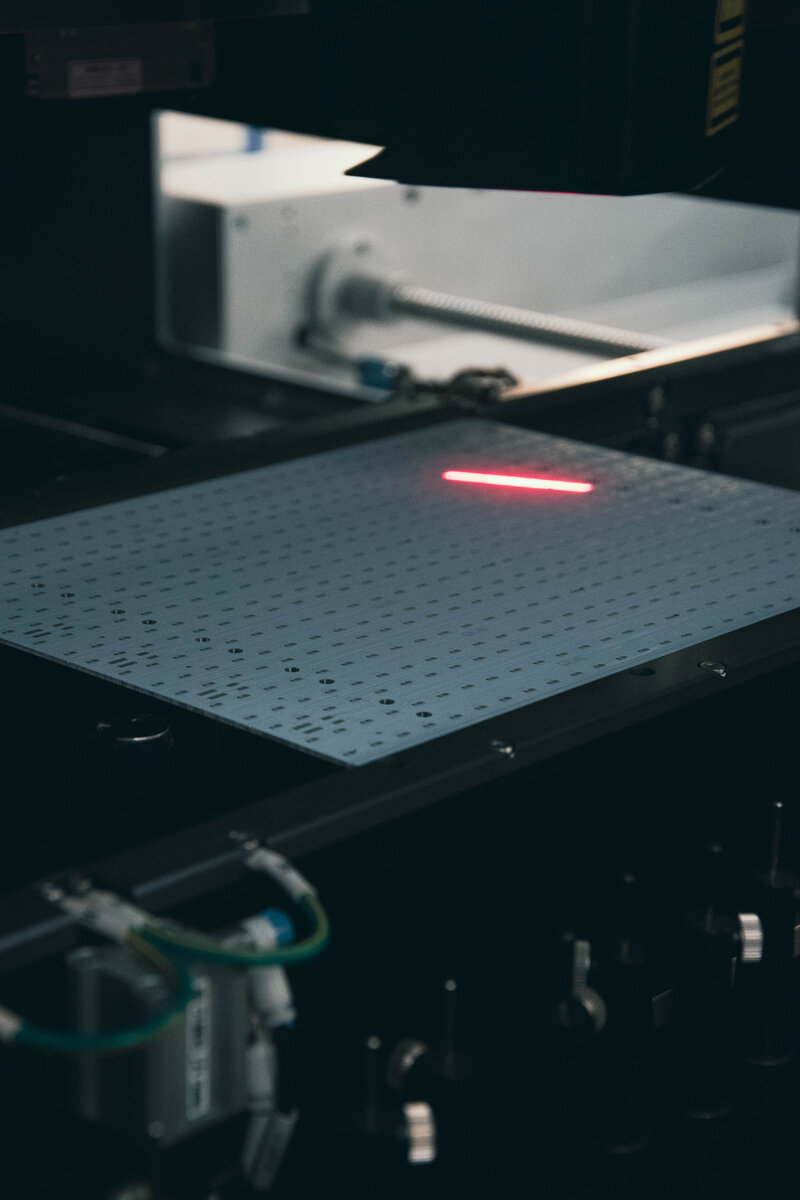

SPI (Solder Paste Inspection)

This innovative system for automatic inspection of solder paste printing is revolutionising inspection processes in electronics manufacturing. An advanced 3D laser sensor head with integrated camera and lighting is used for measurement. With this technology, imaging is done regardless of the colour, material, or roughness of the scanned surface. Thanks to scanning the entire PCB area with the unique PARMI technology and real-time Z-axis control, PCB deflection is mitigated. The high-precision head movement system provides high resolution movement down to 0.1 µm.

The machine also automatically compensates for the PCB's stretch and shrinkage coefficient data, comparing its value to the Gerber batch files.

SPI not only streamlines production, but also minimises the risk of errors, increasing the efficiency and quality of the entire process. It is a modern approach to quality control that enables the company to achieve higher standards in solder paste printing.

Reflow Soldering Lurnance (SMT)

The high-performance convection reflow soldering furnace offers optimised soldering in a lead-free process for the highest productivity and efficiency. Unique closed-loop convection control ensures precise heating and cooling. Programmable heat transfer and lower nitrogen consumption result in significant cost reductions.

The Pyramax reflow furnace is equipped with BTU's proprietary WINCON™ software, the world's most powerful reflow soldering furnace control system. WINCON features a simplified user interface and Energy Pilot software, which offers extremely powerful analysis capabilities for reflow soldering.

AOI (Automated Optical Inspection)

The state-of-the-art Automatic Optical Inspection (AOI) System is revolutionising the inspection processes for components mounted on printed circuit boards. This innovative machine uses world-unique dual laser beam scanning technology to achieve one of the fastest scanning speeds available on the market.

With high-quality full 3D imaging of the entire PCB, the AOI system is able to detect defects regardless of the colour, material, or roughness of the surface. It automatically identifies a number of irregularities related to the installed components, such as missing or misaligned components, wrong dimension, side mounting, upside-down mounting, the tombstone phenomenon, lift, solder quality, strip colours, raised or buckled feet, short circuit or polarisation.

Specialised software also makes it possible to check for the presence of foreign matter and contamination on electronic modules, while analysing the correct alignment of components without the need for additional teaching. The AOI system accurately measures the deflection of the entire panel, eliminating measurement errors.

Components up to 65 mm in height can be inspected using the multi-stage scanning method. In addition, dual lasers mounted at an exceptionally sharp projection angle allow 3D imaging of short components adjacent to tall ones.

The entire system allows real-time image collection, making it easier to locate defects during inspections. At the verification station, you can easily see where the error occurred by scanning the module code and analysing each case using the stored images. This modern approach to component inspection allows you to achieve the highest standards in electronics manufacturing quality.

Portfolio

Take a look at our portfolio of projects where we have had the pleasure of working with a variety of clients to deliver comprehensive electronics solutions. They are proof of the high quality of our services as well as our ability to adapt to various customer requirements.

Our technologies and equipment

Our advanced manufacturing infrastructure is equipped with the latest technologies, including SMT machines, THT assembly equipment, conformal coating systems, and electronics testing tools. As a result, we ensure precision and efficiency in executing even the most complex projects.

Quality Certificates and Testimonials

We are proud of our quality certifications, such as ISO 9001, which confirm our commitment to providing high-quality services. We also invite you to read testimonials from satisfied customers who have trusted us with their projects.

Conatct

Contact us at EMS@lug.com.pl or using the contact details provided. We are open to any questions you may have about our services and eager to work with you. You are also welcome to visit our head office, the address of which can be found below.